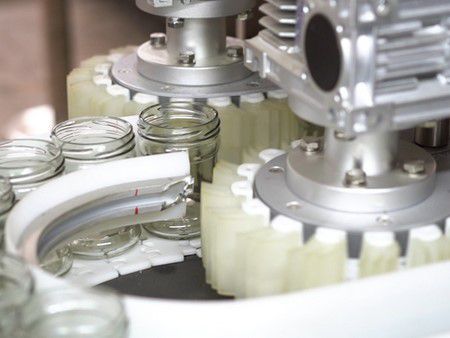

The side-grip bottle rinser features a side grip that holds empty containers, rotate them, and thoroughly cleans them through high-pressure water or cleaning fluids. Its versatility extends to jars, plastic bottles, glass cans, and other containers with large dimensions, making it an ideal choice for a wide array of production needs. Boasting exceptional efficiency and easy operation, this bottle washing machine is set to enhance your packaging process. With dimensions accommodating a range of container sizes (W38-100mm, H50-300mm), the side-grip bottle rinser epitomizes both efficiency and adaptability in one seamless package.

Containers with large dimensions such as jars, hard plastic bottles, glass cans.

This side-grip bottle rinser is widely used in food filling lines, drink filling lines and pharma filling lines to clean juice bottles, wine bottles, medicine containers, etc.

A durable stainless frame, fixed adjustable side-grip conveyors, a multi-touch PLC control system with frequency control.

| Production capacity | 30-40bpm (depending on bottle size) Applicable bottle diameter: 38-100mm Applicable bottle height: 50-300mm |

| Water consumption | 0.5-1.0m³/h |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | 0.3m³/min |

| Total power | 2.0kW |

| Dimensions | 3800×1100×1600mm |

Bottle rinsing machines are primarily used in packaging and filling lines for the cleaning of a variety of containers including plastic bottles, glass bottles, metal cans, and other types of containers.

They are designed to eliminate contaminants such as dust, particles, and grease that may accumulate on bottles during transportation and handling processes.

Yes, the design flexibility of our bottle rinsing machines allows them to accommodate a wide array of bottle sizes and shapes, demonstrating high adaptability within the bottle filling line.

Yes, we provide a diverse range of bottle rinsing machines that can be customized to suit your production line needs. Whether you opt for standard or custom bottle rinser, they are engineered for easy integration into your bottling line.

From individual filling machines to complete packaging lines, we've got covered!